Engine (CS) – Ceramizer for four-stroke petrol, diesel, LPG engines

32,00 €

A preparation that regenerates and protects four-stroke engines of any type.

In stock

Product description

Ceramizer® CS is a preparation for regeneration and protection against wear of the friction surface of the engine. It can be used in all types of four-stroke engines.

Regeneration of the engine is carried out during the usual operation of the vehicle, dismantling the mechanism is not necessary. The only necessary action is to add the preparation to the infusion of engine oil. The ceramic oil additive produces a special ceramic-metal coating that builds up in places of friction of metal parts. Particularly intense action can be observed in the most worn areas.

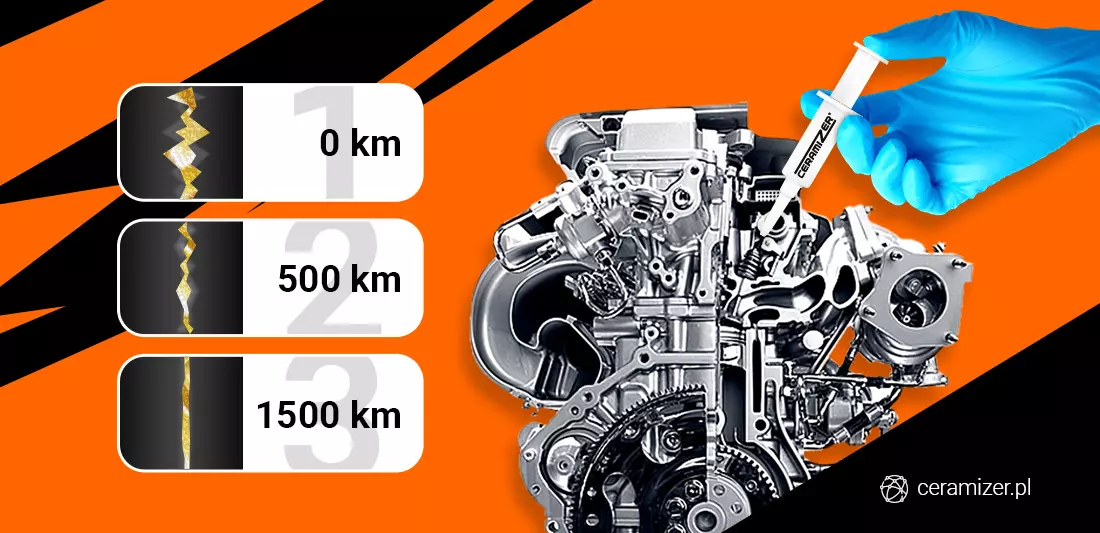

The protection layer, created by the preparation for engine oil, eliminates all deformations and micro-damage to the engine. The use of Ceramizer® allows you to achieve an effect similar to micro-welding an additional layer of material in places that are characterized by the highest wear. The formation of a protective layer continues until about 1500 km is overcome.

Why is it worth using Ceramizer® CS engine regeneration preparation?

- Parts of the engine, subject to frictional forces, are regenerated and become up to 5 times stronger.

- The level of fuel consumption is significantly reduced. The observed savings range from 3 to 15%.

- The engine runs quieter and more stable, and the vehicle moves more dynamically.

- The phenomenon of oil uptake by the engine is significantly reduced.

How to use

| Amount of oil in the engine [L]: | 2-8 L | 9-16 L | 17-24 L | 25-33 L |

|---|---|---|---|---|

| Mileage: 5-50 thousand. Miles | 0.5 dos | 1 dos | 2 dos | 3 dos |

| Mileage: 50-300 thousand. Miles | 1 dos | 2 dos | 3 dos | 4 dos |

| Mileage: >300 thousand. Miles | 2 dos | 3 dos | 4 dos | 5 dos |

Find out more

How does the Ceramizer oil additive work?

Ceramization is an innovative technology that allows you to regenerate engines, gearboxes, bridges and other mechanisms in which there is friction of metal against metal. The ceramic layer is formed by combining and diffusing Ceramizer® molecules with metal molecules moving in the oil. The effect of the ceramization process is the creation of a ceramic-metal layer filling the cavities in the metal structure and restoring the nominal state of the mechanism.

Hassle-free engine regeneration

After applying the Ceramizer® engine oil additive , engine regeneration takes place automatically and does not involve the vehicle user in any way. Only the dose of the oil additive should be applied to the engine oil filler in accordance with the instructions. It is very simple and each driver can do it himself. A visit to the workshop and disassembly of the engine are not required.

Engine preparation that improves work and reduces the risk of failure

The use of the Ceramizer® engine additive allows you to stabilize and improve the operation of the engine. The compression pressure in the cylinders is equalized and the risk of piston ring blockage is reduced. Another significant benefit is the easier cold start of the engine. Regeneration and reinforcement of engine parts significantly reduces the risk of failures and the driver incurring the associated costs.

Safe and environmentally friendly motor ceramics

Ceramizer® products have undergone a number of tests, including industrial tests and oil-free driving tests. The tests carried out proved that the preparation for engine regeneration is completely safe for the engine, and its use is not fraught with the risk of side effects. The protective layer created as a result of its operation allows you to continue driving, even in the event of an emergency oil leak. The mileage between normal oil changes is extended by up to 50%. Vehicles in which the Ceramizer® oil additive is used operate in an environmentally friendly way, because the level of toxic substances contained in the exhaust gases is reduced.